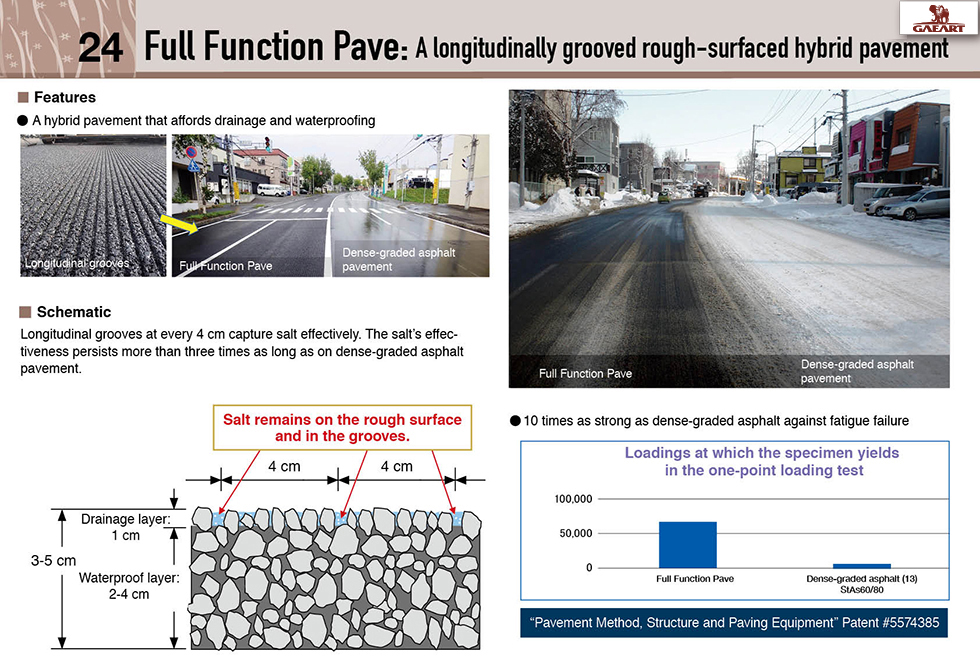

Schematic

Longitudinal grooves at every 4 cm capture salt effectively. Salt’s effectiveness persists more than three times as long as on dense-graded asphalt pavement. The uppermost part of this hybrid pavement’s surface layer drains as well as porous asphalt pavement does. The lower part of the surface layer is as waterproof as crushed stone mastic asphalt pavement. A specially developed asphalt finisher gives the pavement a rough surface with longitudinal grooves. The texture of this rough surface is as deep as that of porous asphalt pavement. This means noise from running tires is reduced and water from rainfall and other sources is controlled. The pavement’s rough surface, longitudinal grooves and compound structure give it additional benefits.

Features

A hybrid pavement that affords drainage and waterproofing. This hybrid pavement has a rough, longitudinally grooved surface. The surface layer promotes drainage, and the pavement affords the same waterproofing as crushed stone mastic asphalt. The rough, longitudinally grooved surface of the pavement is created by using an asphalt finisher, which is an improved version of a compactor. Giving the pavement a rough, longitudinally grooved surface improves traveling safety in rainy environments. Other benefits include freezing control, noise reduction and improved visibility. This pavement reduces traffic accidents.

A specially developed asphalt finisher gives the pavement a rough surface with longitudinal grooves. This rough, longitudinally grooved surface improves drainage, reduces the noise from running tires, mitigates freezing and improves visibility. Skid resistance is also improved.

Drainage

Full Function Pave, whose surface promotes drainage, controls the accumulation of water on the road in wet weather. By controlling the accumulation of water on the road, it’s possible to mitigate hydroplaning and smoking, which contributes to safety in wet weather. Black ice is less likely to form, because the drainage is expected to keep the road surface dry even in winter.

De-icing effects

When salt is spread, the rough surface with longitudinal grooves, which is a notable feature of Full Function Pave, holds the salt on the surface longer than conventional pavement does. The residual salinity on the road is high, so salt spreading is expected to be effective for many more hours than for other pavements. This persistent effectiveness makes it possible for the pavement to remain exposed for longer than conventional pavements would. And with less salt flowing off the road, fewer deployments of salt spreaders are expected to be needed.

De-icing effects

Salt measurement on a road in service (caption). On dense graded pavement, the salinity falls below 1.2% within an hour and a half after salt spreading. This is the salinity standard for Full Function Pave and the lower limit for keeping spread water from become slushy. Even at 5 hours after spreading, the salinity on Full Function Pave hasn’t fallen below the standard value. These results show that Full Function Pave controls freezing better than dense-graded asphalt pavement does.

High durability

This is an example of the results of one-point loading on a specimen fixed at both ends. The Full Function Pave mixture was found to have about ten times the fatigue resistance of the dense-graded asphalt mixture with a straight asphalt binder of 60-80, and about twice the fatigue resistance of polymer Modified Asphalt II mixture.

Patent

Paving Construction Method, Pavement Structure, and Longitudinal Groove Forming Instrument for Pavement : Japanese Patent JP5574385

Paving Construction Method, Pavement Structure, and Longitudinal Groove Forming Instrument for Pavement: Japanese Patent JP5913753

Asphalt Paving Construction Method and Asphalt Finisher: Japanese Patent JP5592867 Asphalt finisher: Japanese Patent JP5913760

Paving Construction Method, Pavement Structure, and Longitudinal Groove Forming Instrument for Pavement : PCT/JP2015/056551

Asphalt finisher: PCT/JP/2015/071751

Contact

Technical Department of the Institute of Construction Technology, GAEART Co., Ltd.

Address:

Kokinu 216-1, Tsukubamirai, Ibaraki Prefecture

e-mail:

” kzusaitou” is followed by “@gaeart.com”

Phone: 0297-52-4751

Fax: 0297-52-2579

URL:http://www.gaeart.com/